|

This

kit

includes

a blower,

mains

power

cord,

air

filter,

flexible

aluminum

ducting

and

hose

clamps.

INLINE

STERILIZATION

SYSTEMS

The

SteriPulse-XL

RS-3000B

and

RS-3000M

systems

can

be applied

in inline

production

applications,

offering

rapid

sterilization.

Model

RS-3000M

systems

can

be configured

with

multiple

Lamp

Housings

to effectively

increase

the

linear

radiation

length.

The

small

bore

lamp

and

elliptical

reflector

provide

high

peak

UV irradiance

for

deep

penetration

and

high

speed

sterilization,

as well

as maximum

energy

for

dose-dependent

sterilization.

The

ability

to implement

remote

Programmable

Logic

Control

(PLC)

for

timed

sterilization

(stop

and

sterilize),

permits

ease

of integrating

RS-3000M

systems

into

small

and

large

scale

manufacturing

systems

LITEMARK-XL

LIGHT

MONITOR

A

useful

accessory

item

that

can

be supplied

with

the

SteriPulse-XL

systems

is the

LiteMark-XL

Light

Monitor.

The

LiteMark-XL

Monitoring

System

is a

photo-electric

detector

module

which

is factory

supplied

mounted

on a

Lamp

Housing

or Sterilization

Chamber

to enable

the

operator

to monitor,

on a

real-time

basis,

the

performance

of a

Pulse

UV Lamp

system

during

its

operating

life.

Such

a capability

allows

the

Pulse

UV Lamp

to be

changed

before

the

output

falls

below

a predetermined

safe

minimum.

It does

this

by sensing

the

light

intensity

from

each

pulse

which

is scattered

sideways

in the

Lamp

Housing

window

and

relating

it to

the

side-scattered

intensity

produced

by the

same

Pulse

UV Lamp

when

new.

The

side-scattered

intensity

produced

by the

new

Pulse

UV Lamp

is designated

as the

“100%

level”,

and

the

intensity

at any

later

time

is compared

to that

100%

level

to produce

a percentage

value

slowly

declining

from

100%

as the

lamp

continues

in use,

indicative

of the

status

of the

Pulse

UV Lamp

at any

given

time.

A correlation

chart

must

be used

in conjunction

with

the

LiteMark-XL

data

to obtain

the

reduced

exposure

percentage.

LiteMark-XL

Mounted

on Lamp

Housing

|

|

MEASUREMENT

OF TARGET

INTENSITY

Since

the

LiteMark-XL

detector

does

not

look

directly

at the

Pulse

UV Lamp

and

is not

located

at the

actual

target

surface,

it does

not

provide

an absolute

calibration

in joules/cm²

of the

energy

striking

that

target

surface.

It does,

however,

provide

an indirect

and

real-time

means

of tracking

the

target

surface

exposure

at any

time

if the

new-lamp

exposure

value

(the

“100%

level”)

has

been

measured

at the

target.

The

correspondence

between

the

actual

target

surface

exposure

at any

time

and

the

reduced

value

derived

from

the

LiteMark-XL

relative

value

and

the

correlation

chart

will

remain

in close

agreement

during

the

entire

effective

operating

life

of the

Pulse

UV Lamp.

The

starting

exposure

(the

100%

level)

at the

target

surface

must

be measured

with

an exposure

(joules/cm2)

measuring

instrument

having

a current

calibration

certification.

The

instrument

calibration

certification

should

cover

the

spectral

range

from

200

nm to

3 microns,

the

nominal

transmittance

range

of the

quartz

components

in the

light

path,

except

in cases

where

narrow-band

exposure

data

is needed.

It should

be noted

that

this

real

time

monitoring

procedure

has

taken

place

without

having

to interrupt

operation

to take

an irradiance

measurement

with

a radiometer.

DATA

LOGGER

SYSTEM

The

incorporation

of the

Data

Logger

System

into

the

LiteMark-XL

Light

Monitoring

System

enables

the

evaluation

process

to be

carried

on continuously

without

the

need

for

operator

calculations

The

Data

Logger

is a

computerized

data

collection

and

analysis

system

which

captures,

records,

processes,

stores

and

prints

radiant

energy

information

from

any

Xenon

Corporation

Lamp

Housing

or Sterilization

Chamber

fitted

with

a LiteMark-XL

Light

Monitoring

system.

The

Data

Logger

interfaces

to a

personal

computer

through

an Analog-to-Digital

Converter

(ADC)

which

is built

into

the

output

connector

of the

Data

Logger

cable,

plugging

directly

into

the

computer

printer

port.

The

system

operator

can

observe

the

Pulse

UV Lamp

intensity

display

on his

computer

monitor

as either

tabulated

data

or as

a graph.

Additionally

the

operator

can

input

the

data

into

an Excel-style

spreadsheet

for

further

processing

off-line.

|

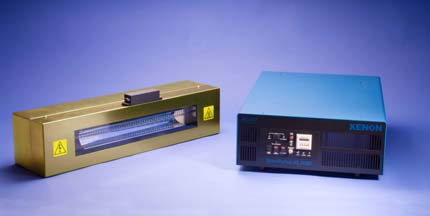

Model

RS-3000M

is a

modular

system

designed

for

ease

of integration

into

large

scale

sterilization

systems.

Units

include

a Controller,

High

Voltage

Power

Supply

Module,

and

a standalone

16"

Lamp

Housing

with

CFQ

lamp.

System

control

is via

a remote

PLC.

Model

RS-3000M

is a

modular

system

designed

for

ease

of integration

into

large

scale

sterilization

systems.

Units

include

a Controller,

High

Voltage

Power

Supply

Module,

and

a standalone

16"

Lamp

Housing

with

CFQ

lamp.

System

control

is via

a remote

PLC.