|

|

|

|

|

|

|

|

Microprocessor Control |

|

|

|

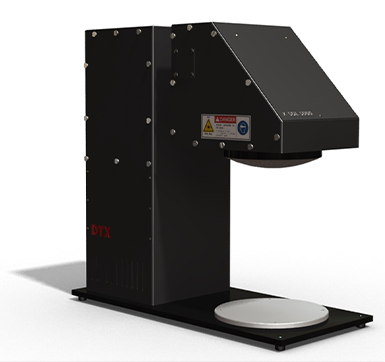

Compact Appearance |

|

|

|

System design for User’s convenience |

|

|

|

High UV Intensity |

|

|

|

Excellent UV Uniformity |

|

|

|

Easy lamp exchange |

|

|

|

Run time Integration of UV lamp |

|

|

|

UV Intensity adjustment by stepping motor (63 Step) |

|

|

|

Remote interface for peripheral equipments |

|

|

|

Remote / Manual Mode |

|

|

|

Various error signal output for safety operation and system

monitoring |

|

|

|

External Interface for PLC or Industrial

PC |

|

|

|

|

|

|

Description |

Specification | |

Model |

EXPO 850 P |

EXPO 850 R |

|

UV Irradiation Direction |

Perpendicular type |

Reflection type |

|

Controller & Lamp Housing |

One body |

One body |

|

Lamp |

High pressure mercury UV lamp

(LTZ 85002 MA) |

|

Lamp Lifetime |

1500 Hr | |

UV Intensity |

10,000 mW/Cm2 at 365nm |

|

UV

Intensity with

Rod lens unit |

Hexag-

onal

135 mm |

365nm |

160mW/Cm2 @ 380mm |

130mW/Cm2 @ 260mm |

|

405nm |

280mW/Cm2 @ 380mm |

220mW/Cm2 @ 260mm |

|

Quadr-

angular

70 mm |

365nm |

380mW/Cm2 @ 90mm |

300mW/Cm2 @ 90mm |

|

405nm |

600mW/Cm2 @ 90mm |

480mW/Cm2 @ 90mm |

|

Quadr-

angular

50 mm |

365nm |

500mW/Cm2 @ 90mm |

400mW/Cm2 @ 90mm |

|

405nm |

900mW/Cm2 @ 90mm |

720mW/Cm2 @ 90mm |

|

Intensity adjustment |

63 Step | |

System Control |

Microprocessor control | |

Shutter control |

Auto mode/ Manual mode (Stepping motor control)

Timer : 0.1 Sec ~ 999.9

Sec ( 0.1 Sec interval) | |

Cooling |

Forced air cooling | |

External Interface |

Remote control and monitoring by PLC or Automation system (5 ~ 24V contact by

photo-coupler) | |

Input signal |

Lamp On/Off

Manual/Remote selection

Shutter Open/Close

Intensity

control

Timer reset |

|

Output signal |

Lamp On/Off status

Lamp stabilization status

lamp lifetime

status

Shutter Open/Close status

Ignition fail error

Door open

error

Temperature error

Shutter error

Shutter orientation fail

error

Iris orientation fail errorAnd, various errors |

|

Operation Modes |

Manual Mode |

System control by manual |

|

Remote Mode |

System control by peripheral equipments such as PLC, Industrial PC,

etc. |

|

Warming up time |

5 minute | |

Power Supply |

Stabilized power supply by microprocessor control.

Support of constant

light output | |

Safety |

Door interlock

Thermal fuse

Air filter | |

Dimension |

250(W) x 350(D) x 550(H) | |

Operation condition |

Temperature : 5 ~ 35 C, Humidity : less than 70% | |

Power Input |

AC110 / 220V ±10%, 50/60HZ | |

Weight |

Approx. 25 kg |

Approx. 30

kg |

|

|

|

|

ROD

LENS UNIT &

ACCESSORIES |

|

|

|

|

Rod Lens Unit |

|

|

| |

High Pressure Mercury Lamp |

|

|

| |  Light Guide Light Guide

|

| |

|

|

| |

|

|

|

|

|

|

|

|

|

UV

INTENSITY WITH

ROD LENS UNIT |

|

|

|

Rod lens

type |

Wavelength |

EXPO

850

P |

Height |

EXPO

850 R

|

Height | |

Hexagona

135 mm |

365 nm |

160 mW/Cm2 |

380 mm |

130 mW/Cm2 |

260 mm | |

405 nm |

280 mW/Cm2 |

380 mm |

220 mW/Cm2 |

260 mm | |

Quadrangular

70 mm |

365 nm |

380 mW/Cm2 |

90 mm |

300 mW/Cm2 |

90 mm | |

405 nm |

600 mW/Cm2 |

90 mm |

480 mW/Cm2 |

90 mm | |

Quadrangular

50 mm |

365 nm |

500 mW/Cm2 |

90 mm |

400 mW/Cm2 |

90 mm | |

405 nm |

900 mW/Cm2 |

90 mm |

720 mW/Cm2 |

90 mm |

| |

| |

| |

* Above specification can be changed without notification for our quality

improvement. | |

| |

| |

|

|

|

|

|

|

|

|

|

|

|

APPLICATIONS |

|

|

|

Semiconductor wafer exposure, FPD edge exposure | |

UV curing for DVD bonding | |

Various Spot UV curing and surface treatment fields such as Semiconductor,

Communication, Display (LCD, PDP), and etc. | |

All manufacturing industries using UV curable adhesive, paints, bonds on

various part’s bonding, curing, drying process.

|

|

|